How well does an alc sheet perform in resisting water seepage in humid environments?

Release Time : 2025-12-01

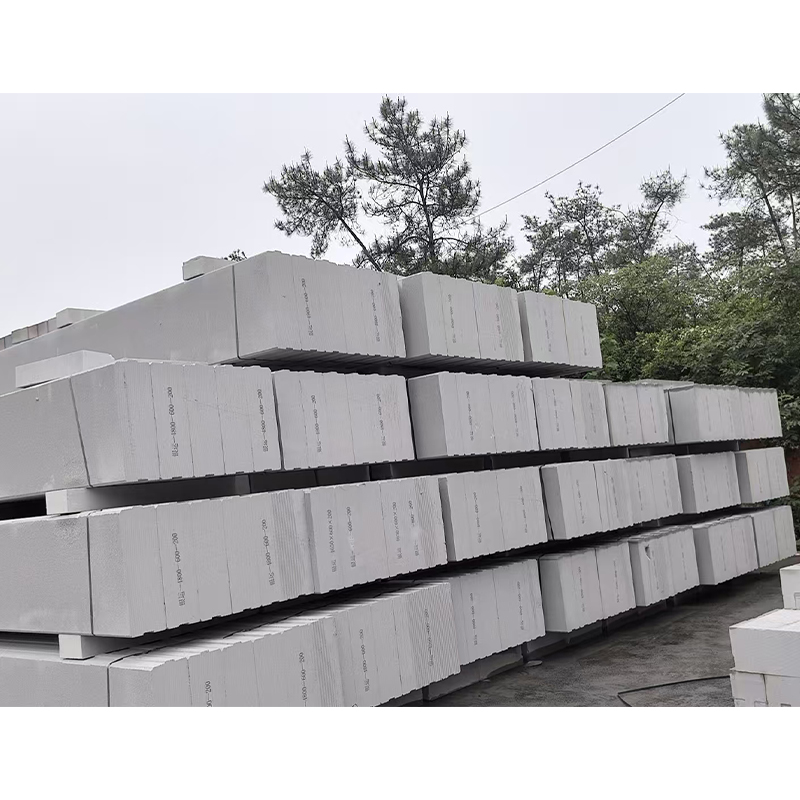

The impermeability performance of ALC sheet (autoclaved aerated concrete panel) in humid environments requires comprehensive analysis from multiple dimensions, including its material properties, structural characteristics, and protective measures. As a porous, lightweight building material primarily composed of calcium silicate hydrate, ALC sheet exhibits good adaptability to humid environments through unique physical and chemical mechanisms. However, its performance is still influenced by factors such as material ratios, manufacturing processes, and application scenarios.

The impermeability of ALC sheet stems from its closed porous structure. Its internally distributed, evenly distributed micropores are mostly independent and closed. This structure not only gives the panel its lightweight properties but also restricts the continuous penetration path of water within the material. When water comes into contact with the panel surface, some water is absorbed by the surface pores, but due to the lack of connectivity between pores, water cannot penetrate deeply into the interior of the panel. Compared to traditional clay bricks, ALC sheet has a more uniform pore structure and smaller pore size, further reducing water diffusion efficiency. This characteristic allows it to effectively prevent water penetration in short-term humid environments (such as bathroom walls), protecting the building structure.

Chemical stability is another key factor supporting the impermeability of ALC sheets. The main component of the board, calcium silicate hydrate, exhibits excellent durability in water and will not dissolve or crumble due to water absorption, unlike gypsum products. Laboratory simulations of static water immersion at room temperature show that after 30 days of immersion in water, ALC sheets show no softening or chipping on the surface, and retain over 85% of their compressive strength, far exceeding that of gypsum board (below 50%). This chemical stability ensures that the board maintains its structural integrity in long-term humid environments (such as basements), avoiding the risk of leakage due to material deterioration.

Although ALC sheets possess natural impermeability advantages, their porous structure can still lead to a certain degree of water absorption. Under standard conditions, the volumetric water absorption rate of ALC sheets is typically between 20% and 25%, reaching up to 30% when saturated. However, this water absorption process has a clear saturation point—once the internal pores are filled with water, the board stops absorbing water. Furthermore, ALC sheets expand slightly upon absorbing water (linear expansion rate approximately 0.1%-0.2%), and shrinkage after drying is slightly less than the expansion rate. This "wet expansion, dry shrinkage" characteristic necessitates the inclusion of expansion joints in the design to prevent wall cracking due to dimensional changes. In practical applications, proper structural design (such as setting control joints) can effectively eliminate the impact of minor deformations on the overall integrity of the wall.

To further enhance the suitability of ALC sheets in humid environments, targeted protective measures are required. Surface treatment is crucial: applying a specialized waterproof interface agent (mainly composed of modified acrylic ester) allows it to penetrate 1-2 mm into the sheet surface, sealing surface pores and forming a continuous waterproof membrane, reducing surface water absorption by over 60%. For areas in prolonged contact with water (such as bathroom walls), double-layer protection is necessary: first apply the interface agent, then adhere tiles or install glass curtain walls. The bonding layer between the tiles and the sheet should use cement-based tile adhesive (bonding strength ≥ 1.0 MPa) to accommodate minor deformations of the sheet. The seams are filled with anti-mold sealant to form a complete waterproof system.

In underground environments, the anti-seepage design of ALC sheets requires more complexity. A flexible waterproof membrane (such as SBS modified bitumen membrane) is needed on the exterior of the wall, with a 20mm thick air layer between the membrane and the ALC sheet to prevent condensation buildup. A penetrating crystalline waterproof coating can be applied to the inside of the sheet; its active ingredients can penetrate 3-5mm into the sheet, reacting with cement hydration products to form water-insoluble crystals that block capillary pores. This "rigid-flexible" protection strategy makes ALC sheets perform excellently in semi-humid environments such as underground garages and basements. After 6 years of use, the damp area on the walls of one underground garage was less than 3%, far lower than that of concrete walls (15%).

Practical application cases verify the reliability of ALC sheets in humid environments. A hotel bathroom in Guangzhou used 100mm thick ALC sheets as partition walls, with a surface treatment of interface agent and tiles, and the seams sealed with anti-mold sealant. A 200mm high concrete curb was installed at the bottom. After five years of use, the walls showed no signs of dampness or mold, and the hollow tile rate was less than 2%, far superior to light steel keel gypsum board partition walls (15% hollow rate). In exterior wall applications in rainy southern regions, a 200mm thick ALC sheet was coated with an elastic exterior wall paint (including a waterproof and breathable layer), with joints filled with weather-resistant sealant and foam rods. An eaves were installed at the bottom to shield against rainwater, resulting in a wall seepage rate of only 0.5%, superior to traditional aerated concrete block exterior walls (5% seepage rate).

ALC sheet exhibits excellent impermeability in humid environments. Its closed-cell porous structure, chemical stability, and manageability provide a foundation for moisture-proofing. Through surface waterproofing treatment, optimized structural design, and targeted construction techniques, ALC sheet can fully meet the requirements of humid environments such as bathrooms, kitchens, and underground projects, providing buildings with a solution that combines environmental protection, energy saving, and moisture-proofing. With the continuous advancement of moisture-proofing technology, the application prospects of ALC sheet in humid environments will become even broader.