How to ensure a secure connection when installing autoclaved aerated concrete boards (ALC boards)?

Release Time : 2025-11-17

For autoclaved aerated concrete boards (ALC boards), ensuring secure connections is crucial for the safety and stability of the wall structure during installation. This connection security requires comprehensive control over seven aspects: material selection, fixing methods, joint treatment, crack prevention measures, pipeline installation, corner reinforcement, and construction specifications, forming a systematic technical framework.

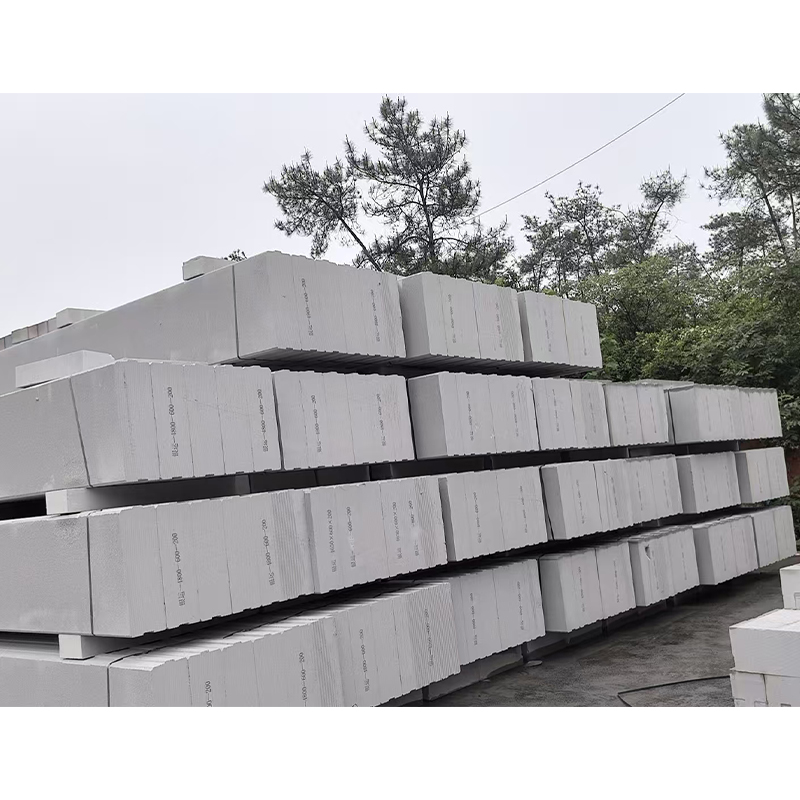

Material selection is fundamental. ALC boards must undergo rigorous inspection before arrival to ensure they are free of cracks, missing corners, and other defects, and that their dimensions meet design requirements. The moisture content of the boards must be controlled within a reasonable range to avoid dimensional deviations or loose connections due to moisture changes. Matching anchors, adhesives, and other auxiliary materials must be compatible with the board properties; for example, using corrosion-resistant fasteners such as stainless steel expansion bolts and U-clamps can prevent corrosion-induced connection failure.

The fixing method should be flexibly selected based on the type of board and the installation location. For interior wall installation of autoclaved aerated concrete boards, U-shaped clips or pipe clamps are commonly used. U-shaped clips are fixed to structural beams or floor slabs using nails, and then the boards are clipped into the top. Pipe clamps require pre-installing pipe clamps on the ends of the boards, which are then fixed to the structural layer using nails or welding. For exterior wall installation, a hook bolt method can be used, connecting the boards to the main structure with angle steel and bolts to enhance wind pressure resistance. Regardless of the method, it is essential to ensure that the spacing between fixing points meets specifications and that the anchors are embedded to the required depth to prevent board displacement due to insufficient fixing.

Joint treatment is crucial for a secure connection. Connections between the boards and concrete columns, walls, and beams should be flexible or rigid, depending on design requirements. For flexible connections, gaps are left at the ends and filled with PE foam to accommodate structural deformation; for rigid connections, polymer mortar is used to fill the gaps to ensure direct force transmission. Wooden blocks or steel connectors should be pre-embedded on both sides of door and window openings, and fixed to the door and window frames with self-tapping screws or flat steel. The horizontal panel above the door should have shoulder cuts on both sides, and the overall integrity should be enhanced by cast-in-place precast beams or downturned beams to prevent cracking caused by opening and closing impacts.

Crack prevention measures directly affect the durability of the connection. For panel joint treatment, the gaps should be cleaned first, and alkali-resistant fiberglass mesh should be adhered with crack-resistant mortar, covering a certain area on both sides of the panel joint to form a flexible transition layer. Corners should be reinforced with dowels, and steel bars should be driven in along the wall height to enhance the shear resistance of the joints. For grooves for water and electricity pipelines, positioning lines should be marked first, and grooves should be cut longitudinally with a special cutting machine. The depth should not exceed a certain proportion of the panel thickness. After laying the pipelines, the grooves should be filled with polymer mortar and reinforced with mesh to prevent the pipeline layout from weakening the panel strength.

Pipeline installation must be coordinated with panel installation. Avoid grooving in panel joints or weak areas. Grooving locations should avoid main load-bearing reinforcements, and transverse grooves should not be cut. When laying pipelines, pipe clamps must be used for fixation to prevent loosening and compression of the panels. For locations requiring pre-embedded electrical boxes, these should be pre-fabricated at the factory to minimize on-site drilling and avoid damaging the panel structure.

Reinforcing corners and T-shaped walls is crucial for improving overall integrity. L-shaped and T-shaped corners require reinforcement with cast-in-place concrete structural columns or angle steel, with reinforcing bars embedded using rebar anchoring technology to form a reliable connection with the panels. For short-limb walls or door jambs, when dimensions are insufficient, cast-in-place reinforced concrete reinforcement is necessary to ensure the joint stiffness meets design requirements.

Construction specifications are fundamental to ensuring connection quality. A specific construction plan must be prepared before installing autoclaved aerated concrete boards, clearly defining the panel layout and installation sequence to minimize the number of vertically embedded panels. During installation, a laser level and straightedge must be used in real-time to correct verticality and flatness, keeping deviations within allowable limits. Before the wall sealant has reached its strength, collisions and vibrations are strictly prohibited to prevent panel misalignment. After installation, a thorough inspection of the panel fixtures is required. Any loose parts should be promptly reinforced to ensure that each panel is securely installed.