How do autoclaved aerated concrete boards reduce overall building energy consumption through their excellent thermal insulation performance?

Release Time : 2025-08-14

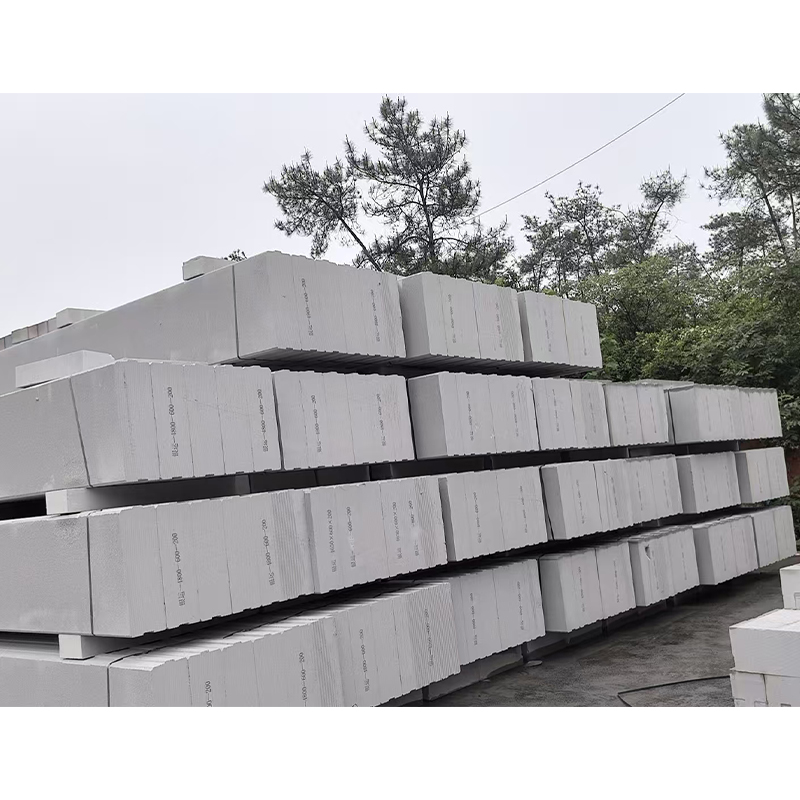

As a new green building material, autoclaved aerated concrete boards have been widely used in prefabricated buildings in recent years. Their unique porous structure and lightweight properties enable them to demonstrate excellent performance in thermal insulation, fire protection, and sound insulation. In particular, the autoclaved aerated concrete boards' pore distribution is more uniform, resulting in a denser structure, further enhancing their thermal performance. This material is not only suitable for interior and exterior walls but is also widely used in floor systems, becoming a key component of modern energy-efficient buildings.

The key to the excellent thermal insulation performance of autoclaved aerated concrete boards lies in their numerous, evenly distributed, closed pores. These tiny pores occupy over 70% of the board's total volume, forming countless "air insulation layers." Because air is a poor conductor of heat, heat cannot effectively transfer through these static pores, significantly reducing the material's thermal conductivity.

In the building envelope, walls and floors are the primary channels for heat loss. Using autoclaved aerated concrete boards as exterior walls or interior partitions effectively reduces heat exchange between indoor and outdoor spaces. They prevent heat loss in winter and prevent high temperatures from entering the building in summer, reducing the load on air conditioning and heating systems. This passive energy-saving design significantly reduces energy consumption throughout the building's lifecycle, improving overall energy efficiency.

The use of autoclave curing further optimizes the thermal insulation performance of autoclaved aerated concrete boards. Unlike traditional atmospheric pressure steam curing or autoclave curing, the autoclave process operates in a high-temperature, high-pressure, saturated steam environment, allowing the cement and siliceous materials to undergo a more complete hydration reaction, forming a more stable tobermorite crystal structure. This also results in denser pore walls, reducing the proportion of large and interconnected pores and enhancing pore closure, further reducing thermal conductivity and improving thermal stability.

In prefabricated building systems, the standardized production and rapid installation of autoclaved aerated concrete boards ensure the integrity and sealing of the building envelope. Compared to traditional masonry walls, which are prone to uneven mortar joints and cold bridges, autoclaved aerated concrete boards utilize a dry construction method, resulting in fewer joints and easier sealing. This effectively prevents heat leakage caused by structural defects and further improves the building's overall thermal insulation.

In addition, the lightweight and high-strength properties of autoclaved aerated concrete boards indirectly contribute to building energy efficiency. Their low weight reduces the load on the building's main structure, thereby reducing the amount of material used in beams, columns, and foundations, and reducing carbon emissions from the production and transportation of building materials. Furthermore, lightweight walls are more suitable for combination with energy-saving systems such as integrated insulation and decorative panels, forming a composite insulation system that achieves even higher energy efficiency standards.

In actual engineering applications, construction projects using autoclaved aerated concrete boards have generally demonstrated significant energy savings. For example, in residential projects in cold regions, the use of 200mm-thick autoclaved aerated concrete boards on exterior walls reduced heating energy consumption by approximately 25% to 30% compared to traditional brick-concrete structures. In regions with hot summers and cold winters, the frequency of air conditioning use in summer is also significantly reduced, significantly improving indoor thermal comfort.

In summary, autoclaved aerated concrete boards, with their unique porous structure, low thermal conductivity, and optimized performance through autoclave curing, can effectively enhance the thermal insulation performance of building envelopes. Combined with the efficient construction methods of prefabricated buildings, they not only save construction time and costs but also reduce operating energy consumption at the source, providing a practical and feasible technical path towards achieving the "dual carbon" goals and promoting the development of green buildings.

The key to the excellent thermal insulation performance of autoclaved aerated concrete boards lies in their numerous, evenly distributed, closed pores. These tiny pores occupy over 70% of the board's total volume, forming countless "air insulation layers." Because air is a poor conductor of heat, heat cannot effectively transfer through these static pores, significantly reducing the material's thermal conductivity.

In the building envelope, walls and floors are the primary channels for heat loss. Using autoclaved aerated concrete boards as exterior walls or interior partitions effectively reduces heat exchange between indoor and outdoor spaces. They prevent heat loss in winter and prevent high temperatures from entering the building in summer, reducing the load on air conditioning and heating systems. This passive energy-saving design significantly reduces energy consumption throughout the building's lifecycle, improving overall energy efficiency.

The use of autoclave curing further optimizes the thermal insulation performance of autoclaved aerated concrete boards. Unlike traditional atmospheric pressure steam curing or autoclave curing, the autoclave process operates in a high-temperature, high-pressure, saturated steam environment, allowing the cement and siliceous materials to undergo a more complete hydration reaction, forming a more stable tobermorite crystal structure. This also results in denser pore walls, reducing the proportion of large and interconnected pores and enhancing pore closure, further reducing thermal conductivity and improving thermal stability.

In prefabricated building systems, the standardized production and rapid installation of autoclaved aerated concrete boards ensure the integrity and sealing of the building envelope. Compared to traditional masonry walls, which are prone to uneven mortar joints and cold bridges, autoclaved aerated concrete boards utilize a dry construction method, resulting in fewer joints and easier sealing. This effectively prevents heat leakage caused by structural defects and further improves the building's overall thermal insulation.

In addition, the lightweight and high-strength properties of autoclaved aerated concrete boards indirectly contribute to building energy efficiency. Their low weight reduces the load on the building's main structure, thereby reducing the amount of material used in beams, columns, and foundations, and reducing carbon emissions from the production and transportation of building materials. Furthermore, lightweight walls are more suitable for combination with energy-saving systems such as integrated insulation and decorative panels, forming a composite insulation system that achieves even higher energy efficiency standards.

In actual engineering applications, construction projects using autoclaved aerated concrete boards have generally demonstrated significant energy savings. For example, in residential projects in cold regions, the use of 200mm-thick autoclaved aerated concrete boards on exterior walls reduced heating energy consumption by approximately 25% to 30% compared to traditional brick-concrete structures. In regions with hot summers and cold winters, the frequency of air conditioning use in summer is also significantly reduced, significantly improving indoor thermal comfort.

In summary, autoclaved aerated concrete boards, with their unique porous structure, low thermal conductivity, and optimized performance through autoclave curing, can effectively enhance the thermal insulation performance of building envelopes. Combined with the efficient construction methods of prefabricated buildings, they not only save construction time and costs but also reduce operating energy consumption at the source, providing a practical and feasible technical path towards achieving the "dual carbon" goals and promoting the development of green buildings.