How do autoclaved aerated concrete boards reduce a building's weight while maintaining strength?

Release Time : 2025-07-31

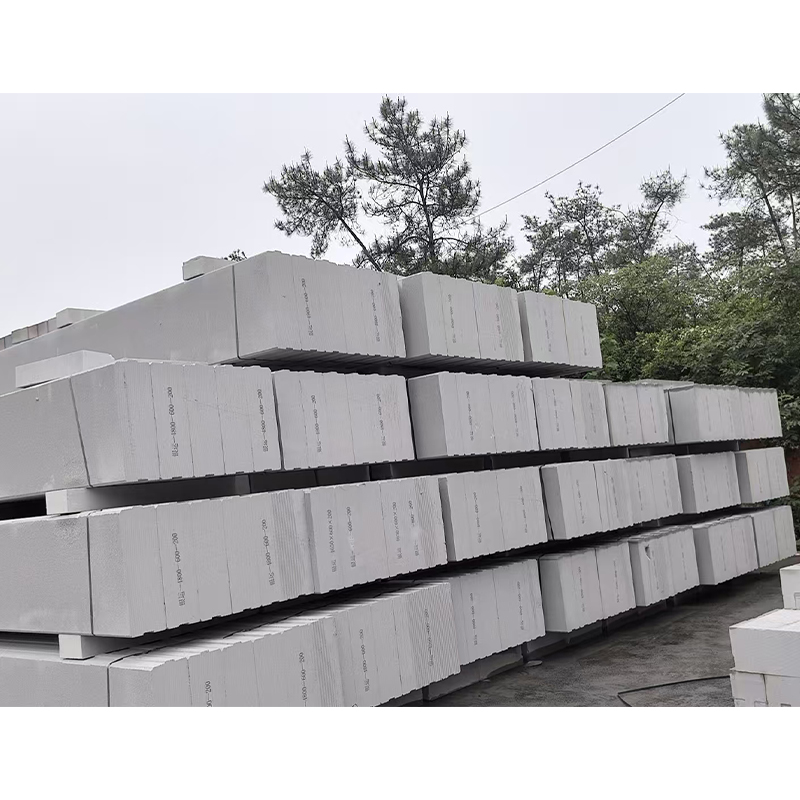

In modern construction, the demand for lightweight, high-strength materials is growing. Autoclaved aerated concrete boards stand out among many building materials due to their unique physical properties and superior performance. They not only offer excellent thermal insulation, sound insulation, and fire resistance, but also significantly reduce a building's weight while maintaining structural strength.

1. Material Composition and Microstructure

The core of autoclaved aerated concrete boards lies in their unique material composition and microstructure. AAC's main components include cement, lime, silica sand, and a foaming agent such as aluminum powder. Through a specialized production process, these raw materials undergo a chemical reaction under high temperature and pressure, creating a large number of evenly distributed micropores. The presence of these pores is a key factor in the lightweight nature of autoclaved aerated concrete boards.

Micropore Structure: Autoclaved aerated concrete boards contain numerous closed micropores, typically ranging in diameter from 1 to 3 mm, which account for approximately 80% of the material's volume. This porous structure significantly reduces the material's density, typically between 400 and 700 kg/m³, significantly lower than the 2,400 kg/m³ of traditional concrete.

Uniform Distribution: The pores are evenly distributed within the autoclaved aerated concrete boards, ensuring consistent mechanical properties throughout the material. This not only reduces weight but also avoids uneven strength caused by localized low density.

2. Manufacturing Process and Quality Control

The manufacturing process of autoclaved aerated concrete boards is crucial to their lightweight and high-strength properties. The following are several key steps:

Foaming: During the production process, aluminum powder, acting as a foaming agent, reacts with cement, lime, and water, releasing hydrogen and forming numerous tiny bubbles. These bubbles are evenly distributed throughout the slurry and solidify, ultimately forming a lightweight concrete block or board.

Autoclaving: The formed aerated concrete body is placed in an autoclave for steam curing. Under high temperature and pressure, the chemical reactions within the body are fully completed, further enhancing the material's strength. Autoclaved AAC boards offer enhanced compressive strength and durability.

Precision Cutting and Surface Treatment: To meet diverse architectural requirements, AAC boards are precisely cut before shipment to ensure consistent dimensions and ease of installation. Surface treatments such as polishing and painting can be applied as needed to enhance aesthetics and waterproofing.

3. Optimized Mechanical Properties

Despite the high porosity of autoclaved aerated concrete boards, they maintain excellent mechanical properties. This is primarily due to the following factors:

High-Strength Cementitious Matrix: Despite the high porosity of AAC boards, their matrix material remains a high-strength cement mortar. By optimizing the cement mix and additives, high compressive strength can be maintained while maintaining lightweight. Generally, AAC boards achieve a compressive strength of 3-5 MPa, sufficient for most non-load-bearing wall applications.

Reinforcement Technology: For applications requiring higher strength, such as load-bearing walls or high-rise building exteriors, internal steel mesh or other reinforcing materials can be used to enhance the overall strength of the AAC board. These reinforcing bars are tightly bonded to the concrete, forming a strong composite structure and effectively enhancing the material's load-bearing capacity.

Modular Design: Autoclaved aerated concrete boards are typically manufactured in standardized sizes for easy transportation and installation. Furthermore, panels of varying thicknesses and specifications can be flexibly combined to meet specific needs, ensuring both structural strength and lightweight design.

4. Multiple Benefits of Weight Reduction

The lightweight nature of autoclaved aerated concrete boards offers numerous practical benefits, specifically in the following areas:

Reduced Foundation Load: Due to the low weight of AAC boards, the foundation load on a building is reduced, lowering the requirements for the foundation and reducing the cost and difficulty of foundation work.

Improved Seismic Performance: Lightweight materials help improve the overall seismic performance of a building. Lightweight walls are less likely to collapse during earthquakes, reducing the risk of casualties and property damage.

Simplified Construction Process: Autoclaved aerated concrete boards are lightweight, easy to transport and install, and significantly shorten the construction period. Especially in high-rise buildings, the use of AAC boards can significantly reduce the load on lifting equipment and improve construction efficiency.

Energy Saving and Consumption Reduction: Due to its low thermal conductivity and excellent insulation properties, AAC boards can effectively reduce energy consumption for winter heating and summer cooling, thereby achieving energy conservation and emission reduction.

In summary, autoclaved aerated concrete boards, through their unique material composition, sophisticated manufacturing process, and optimized mechanical properties, significantly reduce the weight of buildings while maintaining structural strength. This not only improves building safety and cost-effectiveness, but also promotes the development of green architecture.

1. Material Composition and Microstructure

The core of autoclaved aerated concrete boards lies in their unique material composition and microstructure. AAC's main components include cement, lime, silica sand, and a foaming agent such as aluminum powder. Through a specialized production process, these raw materials undergo a chemical reaction under high temperature and pressure, creating a large number of evenly distributed micropores. The presence of these pores is a key factor in the lightweight nature of autoclaved aerated concrete boards.

Micropore Structure: Autoclaved aerated concrete boards contain numerous closed micropores, typically ranging in diameter from 1 to 3 mm, which account for approximately 80% of the material's volume. This porous structure significantly reduces the material's density, typically between 400 and 700 kg/m³, significantly lower than the 2,400 kg/m³ of traditional concrete.

Uniform Distribution: The pores are evenly distributed within the autoclaved aerated concrete boards, ensuring consistent mechanical properties throughout the material. This not only reduces weight but also avoids uneven strength caused by localized low density.

2. Manufacturing Process and Quality Control

The manufacturing process of autoclaved aerated concrete boards is crucial to their lightweight and high-strength properties. The following are several key steps:

Foaming: During the production process, aluminum powder, acting as a foaming agent, reacts with cement, lime, and water, releasing hydrogen and forming numerous tiny bubbles. These bubbles are evenly distributed throughout the slurry and solidify, ultimately forming a lightweight concrete block or board.

Autoclaving: The formed aerated concrete body is placed in an autoclave for steam curing. Under high temperature and pressure, the chemical reactions within the body are fully completed, further enhancing the material's strength. Autoclaved AAC boards offer enhanced compressive strength and durability.

Precision Cutting and Surface Treatment: To meet diverse architectural requirements, AAC boards are precisely cut before shipment to ensure consistent dimensions and ease of installation. Surface treatments such as polishing and painting can be applied as needed to enhance aesthetics and waterproofing.

3. Optimized Mechanical Properties

Despite the high porosity of autoclaved aerated concrete boards, they maintain excellent mechanical properties. This is primarily due to the following factors:

High-Strength Cementitious Matrix: Despite the high porosity of AAC boards, their matrix material remains a high-strength cement mortar. By optimizing the cement mix and additives, high compressive strength can be maintained while maintaining lightweight. Generally, AAC boards achieve a compressive strength of 3-5 MPa, sufficient for most non-load-bearing wall applications.

Reinforcement Technology: For applications requiring higher strength, such as load-bearing walls or high-rise building exteriors, internal steel mesh or other reinforcing materials can be used to enhance the overall strength of the AAC board. These reinforcing bars are tightly bonded to the concrete, forming a strong composite structure and effectively enhancing the material's load-bearing capacity.

Modular Design: Autoclaved aerated concrete boards are typically manufactured in standardized sizes for easy transportation and installation. Furthermore, panels of varying thicknesses and specifications can be flexibly combined to meet specific needs, ensuring both structural strength and lightweight design.

4. Multiple Benefits of Weight Reduction

The lightweight nature of autoclaved aerated concrete boards offers numerous practical benefits, specifically in the following areas:

Reduced Foundation Load: Due to the low weight of AAC boards, the foundation load on a building is reduced, lowering the requirements for the foundation and reducing the cost and difficulty of foundation work.

Improved Seismic Performance: Lightweight materials help improve the overall seismic performance of a building. Lightweight walls are less likely to collapse during earthquakes, reducing the risk of casualties and property damage.

Simplified Construction Process: Autoclaved aerated concrete boards are lightweight, easy to transport and install, and significantly shorten the construction period. Especially in high-rise buildings, the use of AAC boards can significantly reduce the load on lifting equipment and improve construction efficiency.

Energy Saving and Consumption Reduction: Due to its low thermal conductivity and excellent insulation properties, AAC boards can effectively reduce energy consumption for winter heating and summer cooling, thereby achieving energy conservation and emission reduction.

In summary, autoclaved aerated concrete boards, through their unique material composition, sophisticated manufacturing process, and optimized mechanical properties, significantly reduce the weight of buildings while maintaining structural strength. This not only improves building safety and cost-effectiveness, but also promotes the development of green architecture.