How to ensure proper rust prevention treatment of reinforcing steel bars during the production of autoclaved aerated concrete (AAC) sheets?

Release Time : 2026-01-26

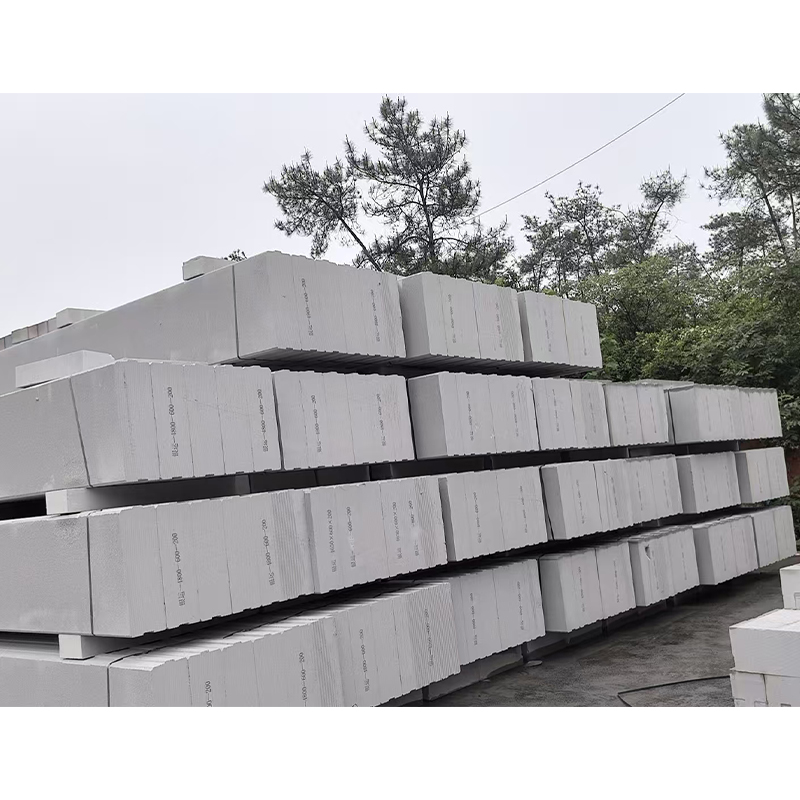

Autoclaved aerated concrete (AAC) sheets are widely used in the construction industry due to their lightweight, high strength, thermal insulation, and environmental friendliness. However, their porous structure and autoclaving process make the reinforcing steel bars within the sheets highly susceptible to corrosion from environmental media, threatening the safety and durability of the sheets. Therefore, ensuring proper rust prevention treatment of the reinforcing steel bars is crucial during AAC sheet production.

In AAC sheet production, rust prevention treatment of the reinforcing steel bars must be controlled from the source. As a structural material, the reinforcing steel bars must meet load-bearing and welding requirements and adapt to the characteristics of autoclaving and other processes. Commonly used reinforcing steel bars must comply with relevant national standards to ensure that their chemical composition and physical properties meet rust prevention requirements. Upon arrival at the site, the reinforcing steel bars must undergo rigorous inspection to ensure they are free of rust, oil stains, and other defects, preventing rust prevention treatment failure due to inherent quality issues with the steel bars themselves.

The core of reinforcing steel bar rust prevention treatment lies in selecting qualified rust inhibitors. Rust inhibitors must possess properties such as high temperature resistance, acid and alkali resistance, and non-toxicity and environmental friendliness. They must be able to firmly bond with reinforcing steel and aerated concrete under autoclaving conditions without powdering, dripping, or deterioration. Traditional rust inhibitors may suffer from poor adhesion and severe corrosion, while new rust inhibitors, through optimized formulations such as the addition of latex, quartz sand, and iron oxide red, significantly improve rust prevention performance and bonding strength, ensuring that the reinforcing steel does not rust for a long time under harsh environments.

The application process of rust inhibitors has a decisive impact on the rust prevention effect. When applying rust inhibitors to the surface of reinforcing steel, it is necessary to ensure that the coating is uniform and without omissions, avoiding corrosion caused by insufficient coating or localized gaps. The construction environment must be kept clean to prevent dust, oil, and other impurities from contaminating the surface of the reinforcing steel, which would affect the adhesion of the rust inhibitor. At the same time, the construction temperature and humidity must be reasonably controlled according to the type of rust inhibitor and construction conditions to ensure that the rust inhibitor forms a dense protective film on the surface of the reinforcing steel.

The autoclaving process is a key step in the production of ALC sheets and a significant challenge in the rust prevention treatment of reinforcing steel. Under high temperature and pressure conditions, rust inhibitors must remain stable, without decomposition or deterioration, to ensure continuous protection of the reinforcing steel. Therefore, rust inhibitors must undergo rigorous high-temperature resistance testing to ensure good rust prevention even under autoclaving conditions. Simultaneously, the heating and cooling rates must be controlled during curing to prevent cracking or peeling of the rust-preventive layer due to sudden temperature changes.

Quality inspection during the production process is crucial for ensuring effective rust prevention treatment of reinforcing steel. A comprehensive evaluation of the rust prevention effect is conducted through visual inspection, coating thickness measurement, and bond strength testing. Non-conforming products must be reworked or scrapped promptly to ensure that all ALC sheets entering the market meet rust prevention requirements. Furthermore, a comprehensive quality traceability system must be established to record key aspects of the production process, enabling rapid identification of causes and implementation of corrective measures when problems arise.

ALC sheet manufacturers need to continuously optimize their reinforcing steel rust prevention technology to adapt to market demands and industry trends. By developing new rust inhibitors, improving construction processes, and strengthening quality inspection, the effectiveness of reinforcing steel rust prevention treatment can be continuously improved, providing strong support for the widespread application of ALC sheets.