What protective measures should be taken when using an ALC sheet in a humid environment?

Release Time : 2025-12-29

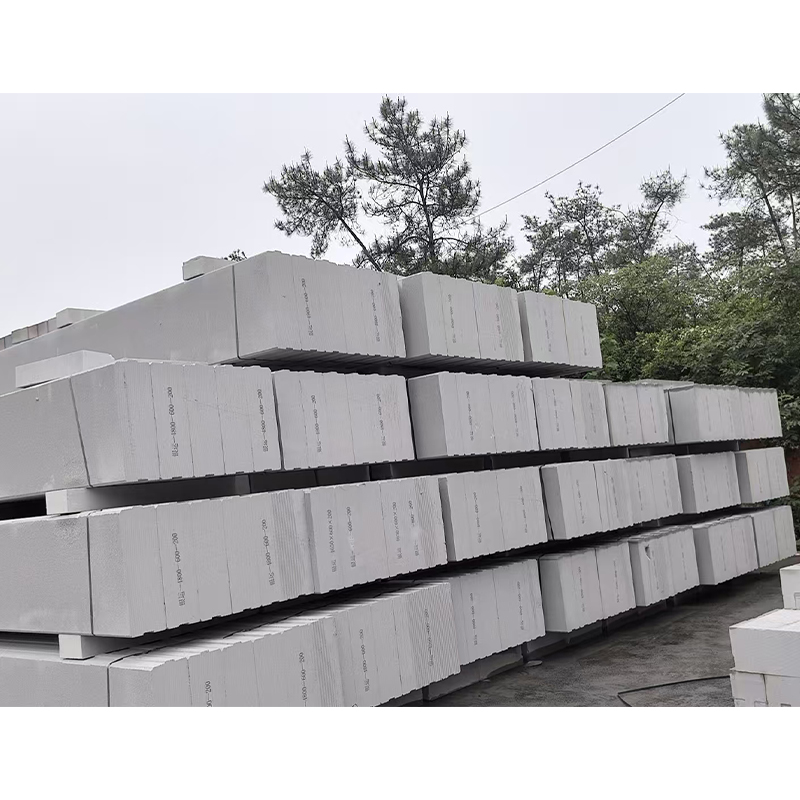

Autoclaved aerated concrete (AAC) sheets are widely used in the construction industry due to their lightweight, high strength, thermal insulation, and environmental friendliness. However, their porous structure makes them prone to moisture absorption and expansion in humid environments, which can lead to mold growth and reduced strength over time. To ensure the long-term stability of AAC sheets in humid environments, comprehensive protective measures are needed across four dimensions: material treatment, structural design, construction techniques, and post-construction maintenance.

Surface treatment is the first line of defense against moisture. AAC sheet surfaces contain numerous micropores, which must be sealed with a specialized waterproof interface agent. Modified acrylic interface agents can penetrate the sheet surface to form a continuous waterproof membrane, reducing water absorption. For areas in constant contact with water, such as bathroom walls, a double-layer protective system is required: first, apply an interface agent to seal the pores, then adhere tiles or install glass curtain walls. The adhesive layer between the tiles and the sheet should use cement-based tile adhesive, which offers high bonding strength and flexibility to accommodate minor deformations of the sheet. Filling seams with anti-mold sealant forms a complete waterproof barrier, preventing moisture from seeping in through gaps.

Optimized structural design is the core of moisture-proofing. In underground projects, a flexible waterproof membrane, such as SBS modified bitumen membrane, should be laid on the outside of the ALC sheet, with an air layer between the membrane and the sheet to prevent condensation buildup. A penetrating crystalline waterproof coating is applied to the inside; its active ingredients penetrate deep into the sheet, reacting with cement hydration products to form water-insoluble crystals that block capillary pores. For high-humidity areas such as bathrooms, a concrete curb at the bottom blocks rising ground moisture, and the connection points to beams at the top are treated with elastic sealant to accommodate structural deformation. Kitchen walls require oil-resistant treatment; an epoxy resin coating is applied over a bonding agent to create a smooth, stain-resistant surface that prevents moisture penetration and facilitates cleaning.

Construction process control directly affects the moisture-proofing effect. After the sheets arrive on site, they should be stored in a dry, well-ventilated place, and the moisture content should be controlled within a certain range before construction. Outdoor work is not recommended during rainy weather. Wall finishing layers should only be applied after the substrate is completely dry; on-site hygrometer testing can ensure compliance. Before applying waterproof coating, thoroughly clean the surface of the boards to remove dust, oil stains, and other impurities. Apply evenly using brushing or spraying methods, avoiding missed areas or excessive coating. Strengthen the coating in areas prone to water seepage, such as wall corners and door/window openings. Treat openings (such as socket holes and light fixture holes) with waterproof materials. In areas with high groundwater levels, increase the strength grade of the boards, add layers of waterproofing, and install drainage ditches to lower the groundwater level.

Post-construction maintenance is an extension of the moisture-proof system. Regularly clean the board surface using a neutral detergent and a soft brush, avoiding the use of acidic or alkaline substances that could damage the surface. Ventilation reduces indoor humidity, especially during humid seasons, requiring increased ventilation frequency to reduce condensation. Check the sealing of board joints and connections; repair any aging or cracked sealant promptly. For walls with mold, remove the mold layer, apply an anti-mold primer, and then proceed with the finishing treatment. Boards exposed to sunlight for extended periods require sun protection treatment to prevent color fading and surface cracking.

Through comprehensive protection through material surface treatment, optimized structural design, controlled construction processes, and effective post-construction maintenance, ALC sheets can maintain stable performance in humid environments. Real-world application examples show that bathroom partitions using a double-layer protection system exhibit no dampness or mold growth after many years, and have a low rate of tile hollowing. In underground parking garages, a combination of waterproof roll material and penetrating crystalline coating for side walls results in a significantly smaller area of dampness compared to concrete walls. With continuous advancements in moisture-proofing technology, the application prospects of ALC sheets in humid environments will become even broader.