How does ALC sheet meet high fire protection standards and maintain structural integrity in high temperatures?

Release Time : 2025-10-20

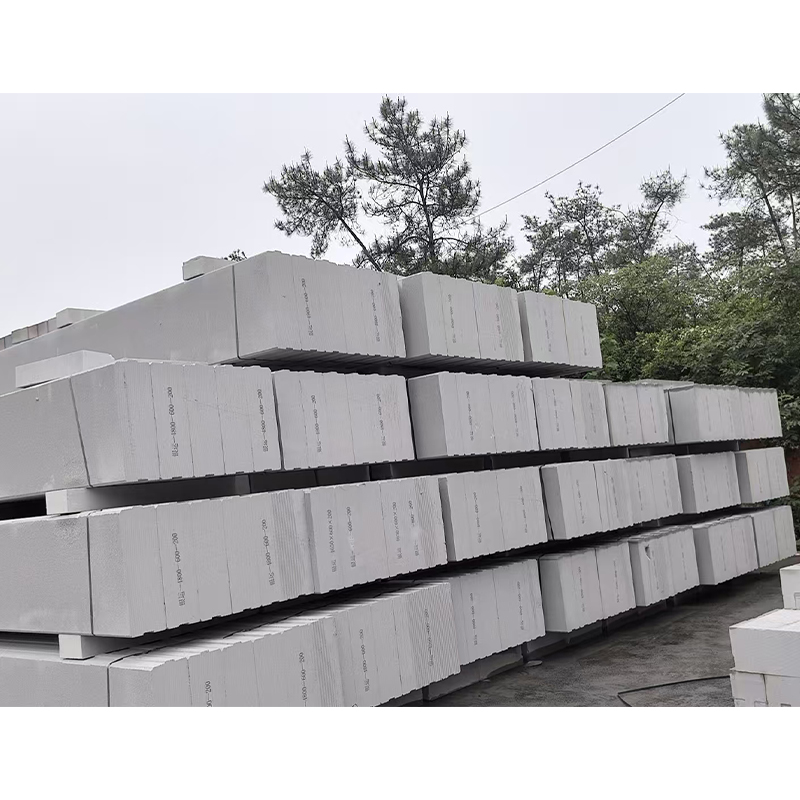

In modern building safety systems, fire resistance is a core criterion for evaluating the value of building materials. When a fire breaks out, components such as walls and floors must not only prevent the spread of flames but also maintain structural integrity at high temperatures, buying valuable time for evacuation and fire rescue efforts. Among various wall materials, ALC sheet (autoclaved lightweight aerated concrete sheet) demonstrates exceptional fire resistance due to its unique material composition and internal structure, making it an ideal choice for high-rise buildings, public facilities, and fire compartmentation designs. Not only is it inherently non-combustible, it also remains stable in extremely high temperatures, creating a solid "fire barrier."

The fire resistance of ALC sheet stems primarily from the inherent properties of its raw materials. It is composed primarily of inorganic minerals such as silicon, calcium, and aluminum, which form a stable crystalline structure through high-temperature autoclaving. These components are inherently non-flammable and do not release flammable gases or combustion-promoting substances at high temperatures. Even when exposed to intense flames, ALC sheet will not burn, melt, or drip like wood or plastic, fundamentally eliminating the possibility of fire spreading through the material itself. Unlike some composite panels that rely on surface fire-retardant coatings, ALC sheet is inherently fire-resistant from the inside out.

More importantly, ALC sheet exhibits exceptional structural stability even at high temperatures. Its interior is permeated with a uniform, fine, and closed pore structure. This porous structure not only contributes to the sheet's lightweight and thermal insulation properties but also plays a crucial role in fire protection. When external temperatures rise sharply, these micropores effectively slow the transfer of heat into the sheet, forming a natural "thermal resistance layer." Heat must gradually penetrate the thin walls between the pores, a process that consumes considerable time and energy, resulting in a very slow temperature rise on the side of the sheet facing away from the fire. Therefore, during a sustained fire, the temperature on the unaffected side of the sheet remains within a safe range, preventing the ignition of adjacent combustible materials or burns.

Furthermore, ALC sheet is resistant to cracking, peeling, or loss of load-bearing capacity in high-temperature environments. Many materials can crack when heated due to uneven expansion or rapid evaporation of moisture, rendering them fireproof. However, ALC sheet undergoes high-temperature autoclaving, releasing its internal moisture in the form of crystallized water. This releases moisture gradually, preventing the generation of intense vapor pressure. Its low coefficient of thermal expansion minimizes deformation upon heating, maintaining the integrity and geometric stability of the overall sheet surface. Even under prolonged flame exposure, the sheet maintains its original shape and strength, continuing to function as a wall or partition, and preventing collapse due to localized structural failure.

In practical applications, this fire-resistant property provides multiple safeguards for building safety. For example, in areas requiring fireproof partitions, such as stairwells, elevator shafts, and equipment rooms, ALC sheet effectively blocks the spread of flames and smoke. In residential partition walls, it can slow the spread of fire from one unit to neighboring units. In commercial complexes, fire compartments help demarcate safe zones and limit the impact of a fire. Thanks to its excellent fire resistance, ALC walls remain unbroken, uncollapsed, and unburned during fires, buying crucial time for escape and firefighting.

Furthermore, ALC sheet does not release toxic smoke or harmful gases during firefighting. In confined spaces, dense smoke from fires is often fatal. As an inorganic material, ALC produces no black smoke or odor when burning, significantly improving visibility and breathing safety in fire environments, further safeguarding lives.

Ultimately, the value of ALC sheet lies not only in its "fire prevention" but also in its "fire resistance"—it not only blocks flames but also stands firm in the face of high temperatures. Using the simplest inorganic minerals, it builds the most reliable passive fire protection system. In every test of intense flames, it stands silently, unburning, undeformed, and unyielding, safeguarding the building's bottom line safety with its sturdy structure. It proves that true fireproofing materials don't need a flashy exterior; they simply need to stand firm in the face of adversity.

The fire resistance of ALC sheet stems primarily from the inherent properties of its raw materials. It is composed primarily of inorganic minerals such as silicon, calcium, and aluminum, which form a stable crystalline structure through high-temperature autoclaving. These components are inherently non-flammable and do not release flammable gases or combustion-promoting substances at high temperatures. Even when exposed to intense flames, ALC sheet will not burn, melt, or drip like wood or plastic, fundamentally eliminating the possibility of fire spreading through the material itself. Unlike some composite panels that rely on surface fire-retardant coatings, ALC sheet is inherently fire-resistant from the inside out.

More importantly, ALC sheet exhibits exceptional structural stability even at high temperatures. Its interior is permeated with a uniform, fine, and closed pore structure. This porous structure not only contributes to the sheet's lightweight and thermal insulation properties but also plays a crucial role in fire protection. When external temperatures rise sharply, these micropores effectively slow the transfer of heat into the sheet, forming a natural "thermal resistance layer." Heat must gradually penetrate the thin walls between the pores, a process that consumes considerable time and energy, resulting in a very slow temperature rise on the side of the sheet facing away from the fire. Therefore, during a sustained fire, the temperature on the unaffected side of the sheet remains within a safe range, preventing the ignition of adjacent combustible materials or burns.

Furthermore, ALC sheet is resistant to cracking, peeling, or loss of load-bearing capacity in high-temperature environments. Many materials can crack when heated due to uneven expansion or rapid evaporation of moisture, rendering them fireproof. However, ALC sheet undergoes high-temperature autoclaving, releasing its internal moisture in the form of crystallized water. This releases moisture gradually, preventing the generation of intense vapor pressure. Its low coefficient of thermal expansion minimizes deformation upon heating, maintaining the integrity and geometric stability of the overall sheet surface. Even under prolonged flame exposure, the sheet maintains its original shape and strength, continuing to function as a wall or partition, and preventing collapse due to localized structural failure.

In practical applications, this fire-resistant property provides multiple safeguards for building safety. For example, in areas requiring fireproof partitions, such as stairwells, elevator shafts, and equipment rooms, ALC sheet effectively blocks the spread of flames and smoke. In residential partition walls, it can slow the spread of fire from one unit to neighboring units. In commercial complexes, fire compartments help demarcate safe zones and limit the impact of a fire. Thanks to its excellent fire resistance, ALC walls remain unbroken, uncollapsed, and unburned during fires, buying crucial time for escape and firefighting.

Furthermore, ALC sheet does not release toxic smoke or harmful gases during firefighting. In confined spaces, dense smoke from fires is often fatal. As an inorganic material, ALC produces no black smoke or odor when burning, significantly improving visibility and breathing safety in fire environments, further safeguarding lives.

Ultimately, the value of ALC sheet lies not only in its "fire prevention" but also in its "fire resistance"—it not only blocks flames but also stands firm in the face of high temperatures. Using the simplest inorganic minerals, it builds the most reliable passive fire protection system. In every test of intense flames, it stands silently, unburning, undeformed, and unyielding, safeguarding the building's bottom line safety with its sturdy structure. It proves that true fireproofing materials don't need a flashy exterior; they simply need to stand firm in the face of adversity.