How to solve the problem of surface peeling of autoclaved aerated concrete boards during freeze-thaw cycles through process improvements?

Release Time : 2025-09-11

The core mechanism of surface spalling in autoclaved aerated concrete boards during freeze-thaw cycles is that the internal pore structure absorbs water, freezes, and expands, leading to an imbalance in stress between the surface and the interior, resulting in delamination. This damage typically begins with microscopic cracks in the surface. With increasing freeze-thaw cycles, these cracks gradually expand into interconnected cracks, ultimately causing widespread spalling. Addressing this issue requires systematic improvements in three areas: optimizing material formulation, controlling production processes, and improving surface protection technologies.

Optimizing material formulation is fundamental to improving frost resistance. The pore structure of autoclaved aerated concrete boards directly affects their water absorption rate, which is a key factor in determining the rate of freeze-thaw damage. By adjusting the ratios of cementitious materials such as cement, lime, and gypsum, the pore distribution can be optimized and the number of large, interconnected pores can be reduced. For example, increasing cement dosage appropriately can improve early strength, but internal stress concentration caused by excessive hydration heat must be avoided. Adding an appropriate amount of mineral admixtures such as fly ash or silica fume can fill micropores and, through pozzolanic reactions, generate low-calcium calcium silicate hydrate, enhancing the density of the interface transition zone. Furthermore, the judicious use of air-entraining agents can introduce evenly distributed microbubbles, which act as pressure relief spaces during freeze-thaw cycles, alleviating ice expansion stresses. However, the dosage must be strictly controlled to avoid strength loss.

Production process control should focus on the pouring, settling, and autoclaving stages. Low-speed mixing should be used during pouring to avoid excessive air introduction and the formation of harmful macropores. Controlling pouring height and speed should also prevent slurry segregation and uneven porosity distribution. During the settling stage, a constant temperature and humidity environment should be maintained to ensure uniform expansion of the green body during the initial setting phase and minimize internal defects. Autoclaving is a critical step in determining the performance of autoclaved aerated concrete boards. A phased temperature rise curve is required: initially, the temperature is slowly increased to 100°C to remove free water, then rapidly increased to 180-200°C in the middle to promote the full reaction of silicate minerals, and finally, the temperature is slowly reduced to prevent thermal stress cracking. Throughout the curing cycle, steam pressure and humidity must be precisely controlled to ensure full crystallization of hydration products and the formation of a dense structure.

Surface protection technology can significantly improve frost resistance and durability. To address the high water absorption of autoclaved aerated concrete boards, surface treatment with a hydrophobic agent can be used. For example, silicone-based hydrophobic agents can form a nanoscale hydrophobic film on the pore surface, reducing water absorption by over 50%. For areas that have already spalled, the loose surface layer must be removed to a solid base layer, then filled with a polymer repair mortar. The material must have an elastic modulus that matches the substrate and a low shrinkage rate to prevent secondary cracking. In addition, drip lines or slopes should be designed in areas prone to water accumulation, such as eaves and window sills, to prevent long-term moisture retention and localized freeze-thaw damage.

Improving structural connection processes can reduce spalling caused by stress concentration. When connecting autoclaved aerated concrete boards to steel structures or concrete frames, flexible anchors, such as spring washers or rubber gaskets, should be used to allow for slight deformation of the board during temperature fluctuations, preventing surface cracking caused by rigid constraints. Connection points should be avoided around board edges and holes, as these areas have low tensile strength and are prone to spalling. For areas where heavy objects are hung, reinforcing ribs or embedded metal fittings should be added to distribute localized loads over a larger area, preventing concentrated stress from causing surface spalling.

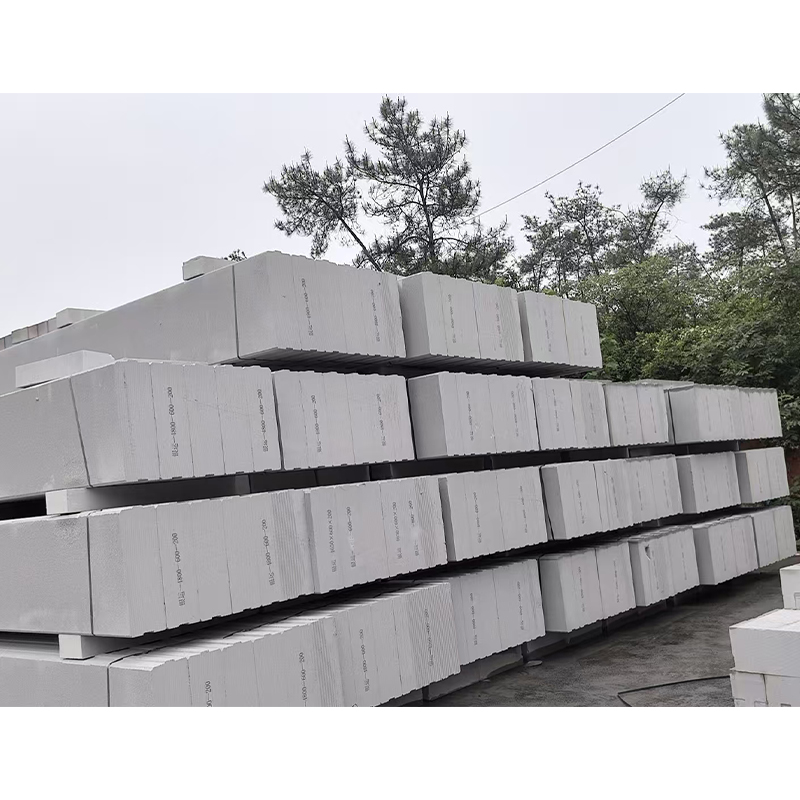

Construction process management is key to ensuring the effectiveness of process improvements. During transportation and stacking, panels should be protected from moisture and mechanical damage. They should be covered with rainproof tarpaulins and stacked in layers using wooden blocks. Before installation, the moisture content of the panels should be checked to ensure they meet design requirements. During installation, verticality and flatness should be maintained to reduce additional stress caused by installation deviations. After construction is complete, the finished product must be protected, such as by covering it with plastic sheeting to prevent rainwater erosion and protect it from freeze-thaw damage before its initial strength is achieved.

Through optimized material formulations, production process control, surface protection technology advancements, structural connection improvements, and construction process management, the problem of surface spalling of autoclaved aerated concrete boards during freeze-thaw cycles can be effectively addressed. These improvements require a systematic approach, encompassing comprehensive control from raw material selection to finished product application, to significantly enhance their frost resistance and durability, meeting the requirements for building envelope structures in cold regions.