Aerated Block Production, Process Flow

Types of aerated blocks:

Sand aeration: The blocks produced by sand materials are sand aeration, mainly showing white, and our company is sand aeration products.

Ash aeration: The blocks produced by fly ash and slag are ash aeration, mainly showing gray appearance.

Ash plus sand: The blocks produced by sand materials plus fly ash and slag are ash plus sand, mainly showing gray color.

The production process of our company is as follows:

1. Granite mud + mountain sand + water abrasive are mixed and mixed, and enter the ball mill through belt conveyor. There are steel forgings inside that collide and grind each other to meet the process requirements. Make slurry.

2. Pouring Add the slurry to the pouring machine, mix and stir with cement, lime aluminum powder and water as auxiliary materials, put it into the mold frame, and produce semi-finished products.

3. When the resting time is up and the curing is successful, cut and peel.

4. Enter the autoclave, and as the pressure slowly increases, reach the required pressure, and perform autoclave curing.

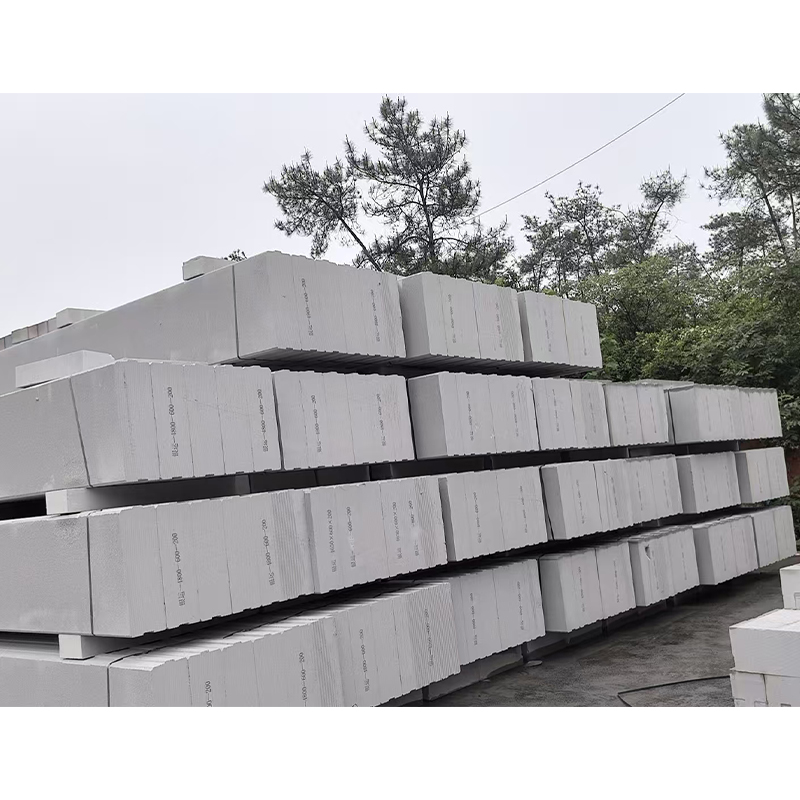

5. Take out of the autoclave, off the line, and stack the finished products. The curing period in the yard is generally 3-28 days. The longer the time, the better the quality.

The local conventional model of our company is: 600x240X200 (mm)

600x240x100 (mm)

Unconventional model (increased cost): 600x200x200 (mm), 600X200x100 (mm)

600x240x120 (mm), 600x200x120 (mm)

600 x240x80 (mm)

Non-standard model (increased cost): 600x240x90 (mm), 600 x240x180 (mm)

Product quality planning:

Conventional: A3.5 B06 (AMU): indicates that A represents superior products. MU represents compressive strength, referred to as A. A3.5: indicates that the absolute dry strength is above 3.5Mpa (megapascals).

B06: indicates the absolute dry mass. The test block of each cubic centimeter is (525g-625g). The new national standard is (550g-650g). The test block of our company is about 560g. Normal production is within 600g.

Conventional ones are: A3.5 B05, A3.5 B06, A5.0 B06, A5.0 Bo7

And so on: A5.0, represents the compressive strength of more than 5.0 MPa.

B07 bulk density is in the range of 625g-725g

Transport damage:

According to the new national standard, the allowable damage rate for transportation is 2%, and 2 bricks are allowed to be damaged for every 100 bricks. The actual situation is subject to the construction site (local requirements are strict and cannot be handed over to the construction site)

Bulk density and strength:

Light bulk density and high strength are of great benefit to construction site. Light bulk density, masonry to the house body, the overall weight is easy to reduce, not easy to collapse, high strength, the wall is not easy to crack, and even will not collapse.